The 32mm brushed planetary gear motor is a compact and efficient solution designed for var...

| Motor Type | Gearbox Model | Gear Ratio | Dimension(mm) |

| S52DPN | 52ZPN□ | 3.65~8.63 | 38.6 |

| 13.53~58.22 | 54.2 | ||

| 67.08~392.98 | 69.8 |

Size: 52mm

Brushed transmission planetary/rated voltage: 24V

Power usage: 25W

Rated speed: 3000RPM

Logistics Sorting

Automated Robots

laser cutting

Access control gate

Photovoltaic Power Station

Medical Devices

AGV

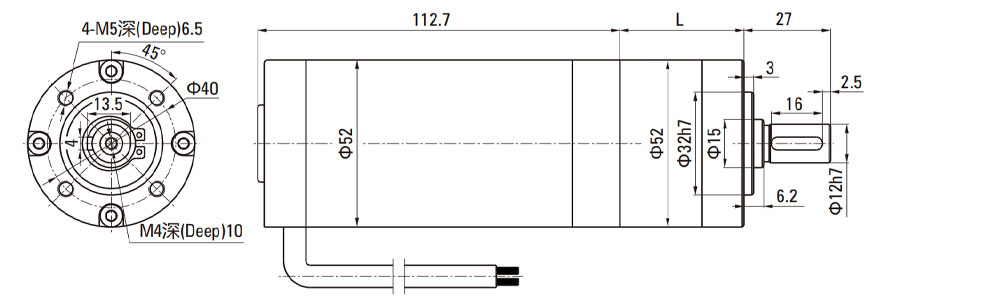

The 52mm brushed planetary gear motor is a compact and efficient solution designed for various applications requiring high torque and precise control. With a diameter of 52mm, this motor is ideally suited for situations where space is at a premium but performance cannot be compromised. The motor operates at a rated voltage of 24V and consumes a power 25 watts, making it energy-efficient while still delivering robust performance.

One of the standout features of this motor is its rated speed 3000 RPM. This high-speed capability, coupled with the torque multiplication provided by the planetary gear system, ensures that the motor can handle demanding tasks with ease. The planetary gear arrangement not only enhances torque but also ensures smooth and consistent operation, reducing the stress on individual gears and extending the motor's lifespan.

Ideal for use in robotics, automation, and small machinery, the 52mm brushed planetary gear motor combines reliability and efficiency. Its compact size and powerful output make it a versatile choice for engineers and designers looking to implement high-performance motion control in their projects.

| Motor Type | Gearbox Model | Gear Ratio | Dimension(mm) |

| S52DPN | 52ZPN□ | 3.65~8.63 | 38.6 |

| 13.53~58.22 | 54.2 | ||

| 67.08~392.98 | 69.8 |

| Motor Type | Voltage V |

Rated Power W |

No-load Current A |

No-load Speed RPM |

Rated Current A |

Rated Speed RPM |

Rated Torque N.m |

Motor Life H |

| S52DPN2440-30S | 24 | 40 | 1.0 | 3500 | 2.5 | 3000 | 0.127 | 2000 |

| S52DPN2460-30S | 24 | 60 | 1.2 | 3600 | 4.0 | 3000 | 0.191 | 2000 |

| Ratio | 3.65 | 5.36 | 6.55 | 8.63 | 13.53 | 18.92 | 24.65 | 28.05 | 33.92 | 44.69 | 58.22 | 67.08 | 81.11 |

| Output shaft speed | 822 | 560 | 458 | 348 | 222 | 159 | 122 | 107 | 89 | 67 | 52 | 45 | 37 |

| Allowable torque | 0.42 | 0.61 | 0.75 | 0.99 | 1.39 | 1.95 | 2.54 | 2.89 | 3.49 | 4.60 | 5.99 | 6.22 | 7.52 |

| Reduction stage | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 |

| Ratio | 91.36 | 102.88 | 118.98 | 127.74 | 145.36 | 165.64 | 191.56 | 231.61 | 301.68 | 392.98 |

| Output shaft speed | 33 | 29 | 25 | 24 | 21 | 18 | 16 | 12 13 |

9.9 | 7.6 |

| Allowable torque | 8.47 | 9.54 | 11.03 | 11.84 | 13.48 | 15.36 | 17.76 | 21.47 | 25.00 | 25.00 |

| Reduction stage | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Brush DC Gear Motors are essential components in many industrial and consumer applications due to their efficiency, reliability, and versatility. In this article, we will explore the diverse applicati...

READ MOREWhen looking to purchase Small AC Gear Motors, it's crucial to consider multiple factors that will determine the motor's suitability for specific applications. Whether for industrial machinery, roboti...

READ MOREChoosing the right gear motor manufacturer is essential for ensuring the efficiency, reliability, and longevity of your industrial applications. Whether you need custom gear motors for industrial appl...

READ MORE