The 32mm brushed planetary gear motor is a compact and efficient solution designed for var...

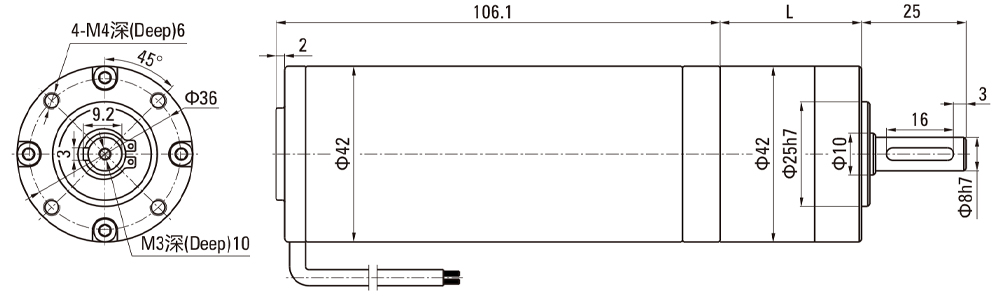

| Motor Type | Gearbox Model | Gea Batio | Dimension(mm) |

| S42DPN | 42ZPN□ | 3.65~8.63 | 33.8 |

| 13.53~58.22 | 47.4 | ||

| 67.08~392.98 | 61 |

Size: 42mm

Brushed transmission planetary/rated current: 0.7-1.1A

Rated torque: 0.024-0.029N.M

Reduction ratio: 3.7-392.98

Logistics Sorting

Automated Robots

laser cutting

Access control gate

Photovoltaic Power Station

Medical Devices

AGV

The 42mm brush planetary gear motor is a versatile and efficient component widely used in various applications requiring precise torque and speed control. With a rated current ranging from 0.7 to 1.1A, this motor is designed to deliver consistent performance while maintaining energy efficiency. Its rated torque falls between 0.024 to 0.029 N.m, ensuring reliable operation under load conditions.

One of the key features of this motor is its broad range of gear ratios, from 3.7:1 to 392.98:1. This wide spectrum allows for significant flexibility in design, making it suitable for diverse applications, from robotics and automation systems to small machinery and tools. The planetary gear design enhances the torque output and improves the efficiency and durability of the motor by distributing the load across multiple gears.

42mm brush planetary gear motor stands out for its combination of compact size, robust performance, and adaptability, making it an ideal choice for engineers and designers looking to optimize their mechanical systems.

| Motor Type | Gearbox Model | Gea Batio | Dimension(mm) |

| S42DPN | 42ZPN□ | 3.65~8.63 | 33.8 |

| 13.53~58.22 | 47.4 | ||

| 67.08~392.98 | 61 |

| Motor Type | Voltage | Rated Rower | No-load Current | No-load Speed | Rated Current | Rated Speed | Rated Torque | Motor Life |

| V | W | A | RPM | A | RPM | Nm | H | |

| S42DPN2425-30S | 24 | 25 | 0.6 | 3500 | 1.6 | 3000 | 0.08 | 600 |

| Ratio | 3.65 | 5.36 | 6.55 | 8.63 | 13.53 | 18.92 | 24.65 | 28.05 | 33.92 | 44.69 | 58.22 | 67.08 | 81.11 |

| Output shaft speed(r/min) | 822 | 560 | 458 | 348 | 222 | 159 | 122 | 107 | 89 | 67 | 52 | 45 | 37 |

| Allowable torque(N.m) | 0.26 | 0.39 | 0.47 | 0.62 | 0.88 | 1.23 | 1.6 | 1.82 | 2.2 | 2.9 | 3.77 | 2.75 | 4.74 |

| Reduction stage | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 |

| Ratio | 91.36 | 102.88 | 118.98 | 127.74 | 145.36 | 165.64 | 19156 | 231.61 | 301.68 | 392.98 | |||

| Output shaft speed(r/min) | 33 | 29 | 25 | 24 | 21 | 18 | 16 | 13 | 9.9 | 7.6 | |||

| Allowable torque(N.m) | 5.34 | 6.01 | 6.95 | 7.46 | 8.49 | 9.67 | 11.19 | 13.53 | 15 | 15 | |||

| Reduction stage | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Brush DC Gear Motors are essential components in many industrial and consumer applications due to their efficiency, reliability, and versatility. In this article, we will explore the diverse applicati...

READ MOREWhen looking to purchase Small AC Gear Motors, it's crucial to consider multiple factors that will determine the motor's suitability for specific applications. Whether for industrial machinery, roboti...

READ MOREChoosing the right gear motor manufacturer is essential for ensuring the efficiency, reliability, and longevity of your industrial applications. Whether you need custom gear motors for industrial appl...

READ MORE