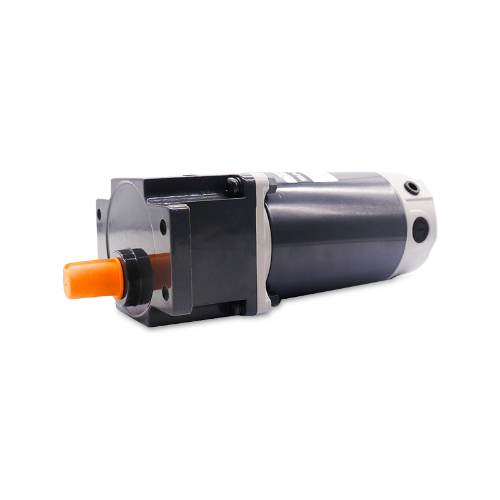

How Do Brush DC Gear Motors Play a Vital Role in Various Industries?

In the rapid development of modern industry and technology, electric motors, as one of the most core power sources, play a crucial role in various fields. In particular, brush DC gear motors, with their unique structural advantages and wide range of applications, have become an indispensable part of many mechanical and electronic devices.

Working Principle of Brush DC Gear Motors

Brush DC gear motors are a combination of a DC motor and a gear system. The DC motor converts electrical energy into mechanical energy through the cooperation of brushes and a commutator, while the gear system transmits power by transferring torque. Compared with traditional DC motors, this type of motor, by adding a gear reduction system to the motor output end, allows the motor to provide higher torque, more precise speed control, and greater load capacity.

The working principle of a brushed DC motor allows for controlling the forward and reverse rotation of the motor through changes in current and brush contact. When the brushes contact the commutator, the current direction changes, thereby changing the rotation direction and speed of the motor. This principle allows the motor to achieve relatively precise speed control and also allows for controlling the output power by adjusting the voltage and current.

Structural Characteristics of Brushed DC Gear Motors

Brushed DC gear motors consist of several core components, each playing a key role in the efficient operation of the motor. The motor's casing, stator, rotor, brushes, commutator, and gear system constitute the complete structure of this motor.

Brushes and Commutator

Brushed DC motors achieve current direction switching through brushes and a commutator. The friction between the brushes and the commutator makes the motor prone to wear during long-term operation, so maintenance and replacement are important aspects of motor use.

Gear System

The main function of the gear system is to convert the high-speed rotation of the motor into low-speed, high-torque output. The gear reduction ratio, material selection, and gear design directly affect the motor's output performance and service life.

Stator and Rotor

The stator is the stationary part of the motor, mainly responsible for generating the magnetic field; the rotor is the rotating part of the motor, which generates motion through the interaction of current and magnetic field. The design of the rotor not only affects the starting performance of the motor but also influences its load capacity.

These core structural components complement each other, ensuring the stability and efficiency of the brushed DC gear motor.

Applications of Brushed DC Gear Motors

Brushed DC gear motors are widely used in various industries, especially in applications requiring high-precision control and high torque output.

Automation Equipment

In equipment such as robots, conveyor belts, and automated production lines, brushed DC gear motors are the preferred power source due to their excellent precision control and high efficiency. The motor speed and torque can be adjusted through an electronic control unit (ECU) to meet the needs of complex automated operations.

Household Appliances

Brushed DC gear motors are commonly found in household appliances such as electric toothbrushes, vacuum cleaners, and washing machines. They use a gear system to reduce speed and provide the required low-speed, high-torque output to drive the equipment to complete daily tasks.

Power Tools

Various power tools, such as electric drills and electric screwdrivers, also widely use this type of motor. Due to their compact structure, high torque, and adjustable power, they are ideal drive systems for these devices.

Toys and Models

Many electric toys, model cars, and remote-controlled aircraft use brushed DC gear motors. Their flexibility and efficiency make the movement of toys more stable and precise, enhancing the interactivity and fun of the toys.

Medical Equipment

In medical devices, especially some small portable devices such as electric wheelchairs and ventilators, brushed DC gear motors also play a crucial role. These devices require high stability and reliability from the motor, and brushed DC gear motors can meet these requirements.

How to Choose the Right Brushed DC Gear Motor?

When choosing a brushed DC gear motor, several key factors need to be considered. These factors not only affect the motor's performance but also directly impact the overall performance of the equipment.

Motor Rated Power and Torque

Choosing the appropriate power and torque is crucial based on the equipment's usage requirements. Too low power may prevent the motor from operating normally, while too high power may lead to unnecessary energy waste.

Gear Ratio and Efficiency

The gear ratio directly determines the speed and torque at the motor output. Different applications may require different gear ratios; therefore, choosing the appropriate gear ratio can not only improve motor efficiency but also extend the motor's lifespan.

Motor Operating Environment

The motor's operating environment has a direct impact on its lifespan and stability. For example, if the motor needs to operate in harsh environments (such as high temperature, high humidity, dust, etc.), a motor with good protective performance should be selected.

Control method and speed control capability

Different applications have varying requirements for motor speed control capabilities. Some applications require precise speed control, while others are less sensitive to speed changes. Therefore, the speed control performance of the motor needs to be selected according to the actual application.

Maintenance and lifespan

Although brushed DC geared motors have high power density and control accuracy, they have certain wear problems due to the presence of brushes and commutators. Therefore, understanding the motor's maintenance cycle and expected lifespan is crucial to ensuring the long-term stable operation of the equipment.

FAQ

1. What are the differences between brushed DC geared motors and brushless DC motors?

The main difference between brushed DC geared motors and brushless DC motors lies in the commutation system. The former uses brushes and a commutator to change the direction of current, while the latter uses an electronic control system for commutation. Brushless motors have a longer lifespan and higher efficiency, but are usually more expensive. In contrast, brushed motors are less expensive and suitable for budget-sensitive applications.

2. Do brushed DC geared motors require regular maintenance?

Yes, brushed DC geared motors require regular maintenance, especially the brushes and commutator. These components will wear out after long-term operation, so they need to be inspected and replaced to ensure the normal operation of the motor.

3. Can brushed DC geared motors be used in high-temperature environments?

The temperature resistance of brushed DC geared motors is affected by their materials and design. Ordinary motors may not be able to operate stably for a long time in high-temperature environments. Therefore, in high-temperature working environments, it is recommended to choose a motor with high-temperature resistance and equip it with a suitable cooling system.

4. How to improve the efficiency of brushed DC geared motors?

Methods to improve motor efficiency include optimizing the motor's load capacity, selecting the appropriate gear ratio, using low-friction materials, and reasonably configuring the cooling system. Ensuring that the motor is operating at its optimal state is also an important factor in improving efficiency.

5. How long is the lifespan of a brushed DC geared motor?

The lifespan of a motor is affected by multiple factors, including the working environment, motor load, and frequency of use. Generally, the lifespan of a brushed DC geared motor is several thousand to tens of thousands of hours. Reasonable maintenance and appropriate working conditions can effectively extend the motor's lifespan.

EN

EN  English

English 中文简体

中文简体 русский

русский Español

Español