The SPE series gearboxes, flange size range with 40, 60, 80, 120, and 160 models, are desi...

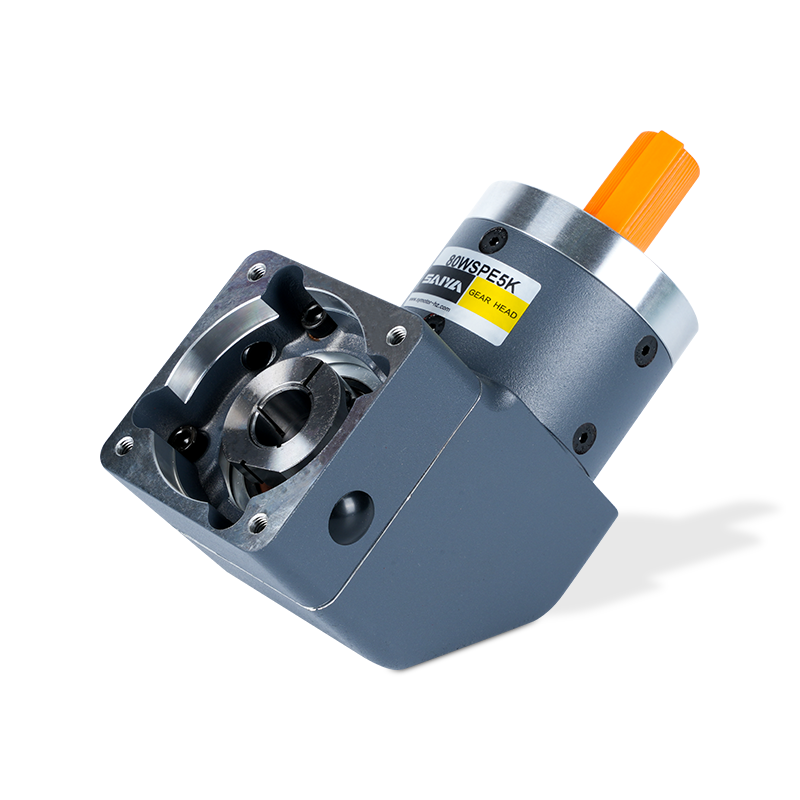

WSPE Series 40 60 80 120

Round output flange

Size range: 40-120mm

Power range: 50W-7500W

Reduction ratio: 3-512

-

Logistics Sorting

-

Automated Robots

-

laser cutting

-

Access control gate

-

Photovoltaic Power Station

-

Medical Devices

-

AGV

Product Description

The WSPE series gearboxes, flange size range dia with 40mm, 60mm, 80mm, and 120mm, are designed to provide efficient and robust power transmission solutions. These gearboxes feature a round output flange, making them suitable for various applications requiring precise and reliable torque transfer. The SPE series suit for motor power from 50W to 7500W, ensuring versatility across different industrial needs.

One of the standout features of the SPE series is its extensive reduction ratio range, from 3:1 to 512:1. This flexibility allows for fine-tuning of speed and torque outputs to match specific operational requirements. The robust construction ensures durability and long service life, even in demanding environments.

The round output flange design not only facilitates easy integration into existing systems but also ensures a secure and stable connection. This design is particularly beneficial in applications where alignment and balance are crucial, such as in robotics, automated machinery, and conveyor systems.

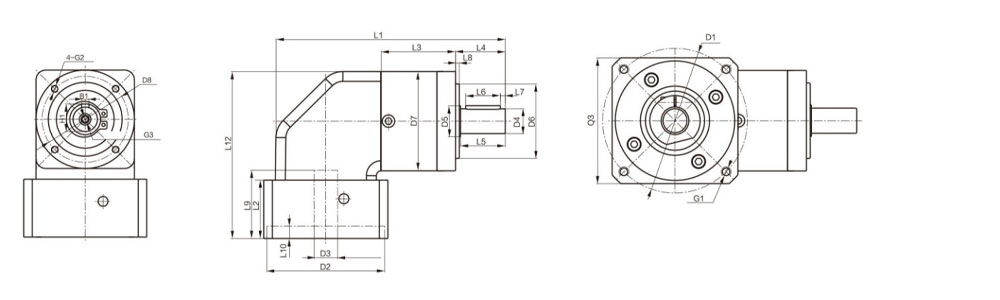

Dimension

| Model | WSPE40 | WSPE60 | WSPE80 | WSPE120 | ||||||||

| Stage | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| Size | (Unit): mm | |||||||||||

| L1 | 119.5 | 132.5 | 144.5 | 156.5 | 169.5 | 182 | 194 | 212 | 229.5 | 258.5 | 286.5 | 314 |

| L3 | 38.5 | 51.5 | 63.5 | 46.5 | 59.5 | 72 | 60 | 78 | 95.5 | 73.7 | 101.5 | 129 |

| L12 | 68 | 93 | 109.5 | 145.5 | ||||||||

| Output End | ||||||||||||

| L4 | 26 | 35 | 40 | 55 | ||||||||

| L5 | 24 | 30.5 | 36 | 50 | ||||||||

| L6 | 16 | 25 | 28 | 40 | ||||||||

| L7 | 2.5 | 2.5 | 4 | 5 | ||||||||

| L8 | 2 | 3 | 3 | 4 | ||||||||

| D4 | φ10h7 | φ14h7 | φ20h7 | φ25h7 | ||||||||

| D5 | φ12 | φ17 | φ25 | φ35 | ||||||||

| D6 | φ26 | φ40 | φ60 | φ80 | ||||||||

| D7 | φ40 | φ60 | φ80 | φ115 | ||||||||

| D8 | φ34 | φ52 | φ70 | φ100 | ||||||||

| B1 | 3 | 5 | 6 | 8 | ||||||||

| H1 | 11.2 | 16 | 22.5 | 28 | ||||||||

| G2 | M4×6 | M5×18 | M6×10 | M10×16 | ||||||||

| G3 | M3×9 | M5×12 | M6×16 | M10×22 | ||||||||

| Input End | ||||||||||||

| L2 | 19 | 23 | 26.5 | 27 | ||||||||

| L9 | 25 | 30 | 35 | 45 | ||||||||

| L10 | 3 | 2.5 | 3.5 | 3.5 | ||||||||

| D1 | φ46 |

φ70 | φ100 | φ115 | ||||||||

| D2 | φ30h7 | φ50h7 | φ80h7 | φ95h7 | ||||||||

| D3 | φ8h7 | φ14h7 | φ16h7 | φ19h7 | ||||||||

| G1 | M4×10 | M5×12 | M6×15 | M8×20 | ||||||||

| Q3 | 40 | 60 | 90 | 115 | ||||||||

-

When looking to purchase Small AC Gear Motors, it's crucial to consider multiple factors that will determine the motor's suitability for specific applications. Whether for industrial machinery, roboti...

READ MORE -

Choosing the right gear motor manufacturer is essential for ensuring the efficiency, reliability, and longevity of your industrial applications. Whether you need custom gear motors for industrial appl...

READ MORE -

Planetary gear motors, as indispensable core components in modern industrial automation, are widely used in various high-precision applications due to their compact and efficient characteristics. They...

READ MORE

EN

EN  English

English 中文简体

中文简体 русский

русский Español

Español