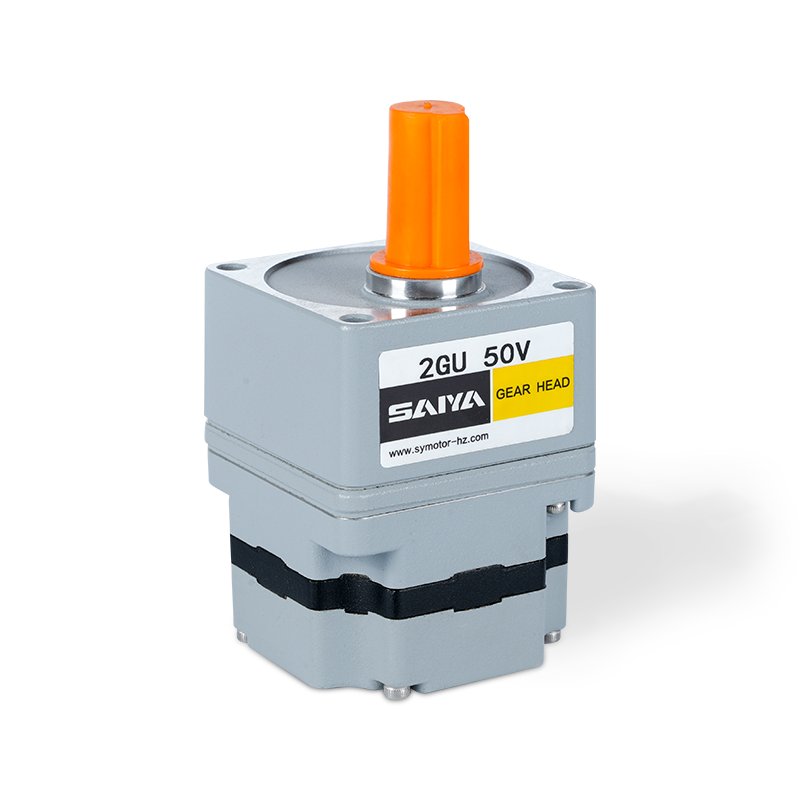

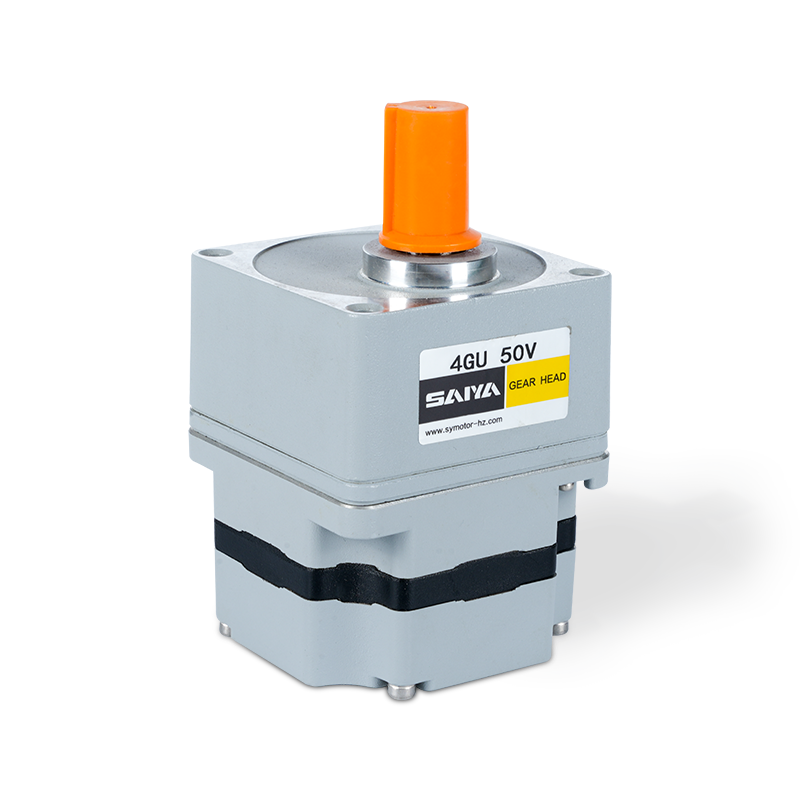

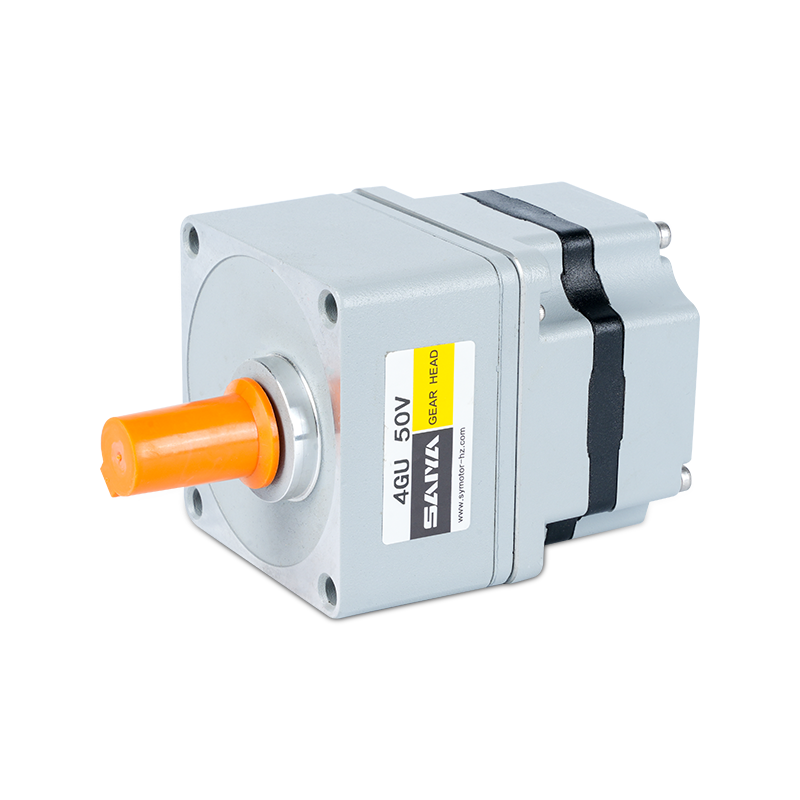

Zhejiang Saiya Intelligent Manufacturing Co., Ltd.

Zhejiang Saiya Intelligent Manufacturing Co., Ltd. established in 2009, with 15 years of industry accumulation, which is a high-tech enterprise specializing in the production and sales of Micro AC gear motors, small AC gear motors, brush DC gear motors, BLDC brushless DC gear motors, Precision Planetary gearbox, and motor roller...etc. We are

China Wholesale 100V-120V Brushless Gear Motor Suppliers and

OEM/ODM 100V-120V Brushless Gear Motor Manufacturers,

Saiya motors and gearboxes are extensively used in industrial robots, intelligent logistics, new energy machines, AGV robots and other advanced fields. Additionally, they serve critical roles in food processing, packaging, textiles, electronics, medical equipment, and specialized machinery, offering cost-effective and differentiated solutions for diverse industries.

To enhance our advantages in differentiation and cost-effectiveness, We have our own trading company, Hangzhou Saiya Transmission Equipment Co., LTD located in Hangzhou, Zhejiang, which is near Shanghai and Ningbo ports, to handle the domestic and overseas business, combined with both direct selling and distribution, ensures global distribution and customer support, providing high-end economical and reliable solution to all our customers.

EN

EN  English

English 中文简体

中文简体 русский

русский Español

Español